Key Takeaways

- Selecting the proper mortar type is essential for brick durability and safety.

- Mortar choice impacts aesthetics, weather resistance, and longevity of brickwork.

- Understanding climate, brick type, and building regulations guides the ideal mortar selection.

- Professional advice, sample testing, and trusted resources help make informed decisions.

- Proper mortar mixing and application are as critical as picking the right type.

Why Mortar Matters for Brickwork

The often underestimated mortar is the foundation behind every lasting brick project. Far more than a filler, it acts as a cushioning adhesive that distributes loads evenly across your brickwork, absorbs minor structural movement, and prevents water from creeping between bricks and causing hidden havoc. Neglecting the importance of mortar can inadvertently cause your walls to suffer from cracks, moisture seepage, and even early collapse in extreme cases. That’s why industry professionals emphasize a thoughtful approach to mortar selection as any project’s first and vital step. If you’re unsure where to begin or want to avoid those classic pitfalls, it’s smart to seek insight from trusted masonry services in your area to get a custom assessment for your project’s exact demands. Just as importantly, mortar is the thread that ties together the brickwork’s look, weather resistance, and long-term structural integrity. The right mortar not only keeps bricks securely in place through storms and sweltering sun but also preserves or even elevates the overall appearance of your project. Conversely, picking the wrong mix can result in unsightly joints, mismatched colors, and weakened exterior walls. Over time, these errors invite damage from rain, shifting temperatures, and daily wear and tear, proving that prudent mortar selection is a future-proof investment.

Common Types of Mortar Used in Brickwork

Mortar comes in a few basic types, each denoted by a letter—N, S, M, and O. Every variety is formulated with a slightly different blend of cement, lime, and sand, resulting in different strengths and flexibilities better suited to specific applications. For example, Type N is the all-rounder: moderately strong and flexible, used widely for exterior walls, chimneys, and above-grade applications where the structure isn’t carrying huge loads. Meanwhile, Type S is the go-to for jobs requiring extra muscle, such as below-grade projects, retaining walls, and areas prone to high wind or seismic shock, offering high strength and good resistance to soil pressure. At the top of the strength scale, Type M is designed for heavy-duty applications like foundations and driveways, supporting the most significant compression loads, but is usually too rigid for older or softer bricks. Lastly, Type O brings a gentler touch, with lower compressive strength suitable for delicate interior brickwork and historic restoration. Each is vital in the right setting but disastrous in the wrong one. As the National Park Service highlighted, mismatched mortar can accelerate brick decay, especially on heritage properties where compatibility with aged brick is crucial to preventing spalling or crumbling.

Factors Influencing Mortar Choice

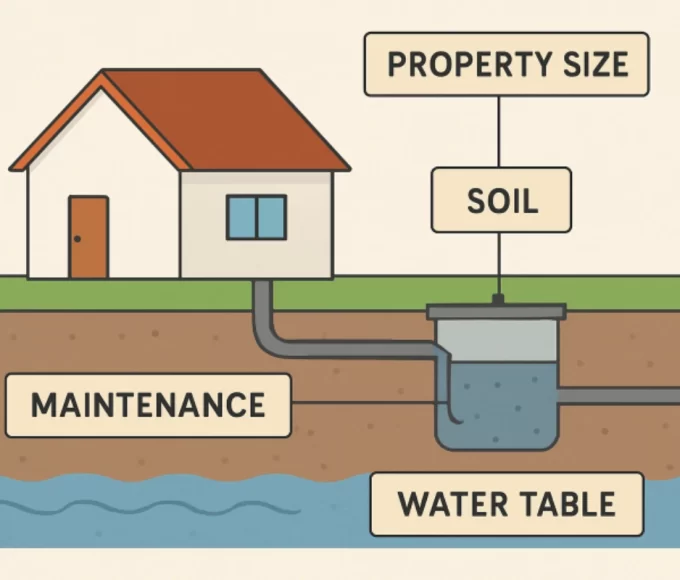

Deciding which mortar to use is not as simple as picking a bag off the shelf. Multiple variables must be considered to guarantee lasting results and hassle-free maintenance. Start with the brick type; some older or handmade bricks are much softer than modern, factory-produced varieties, requiring a more forgiving mortar (often Type O or a custom blend). The intended load and use are also a driver—will your brickwork decorate a garden or bear the weight of a multi-story structure? Environmental exposure cannot be ignored. Walls exposed to regular rainfall, freezes, or salt air must use mortar that resists water absorption and doesn’t become brittle in fluctuating temperatures. Color and finish are essential for aesthetic harmony, especially on visible facades or repairs. You’ll also want to consult local building codes or preservation requirements, which may dictate mortar standards, primarily if you work in a historic zone. Each of these parameters influences durability and repair logistics in the years ahead.

How to Match Mortar to Your Project

It’s easy to underestimate the challenge of finding a perfect mortar match, but following a thorough step-by-step process helps avoid disappointment. First, accurately define your brickwork’s role—structural or decorative, above or below grade. Refer to up-to-date industry recommendations based on brick type and wall function. The secret to satisfaction is a small-scale mortar trial. Before committing your whole wall, prepare and apply a test joint (or panel) in an out-of-the-way spot. Check cured samples for strength, color, and texture against your chosen bricks and setting. Adjust the mix if the results are off, tweaking sand color, lime ratio, or water content as needed. In sensitive or unique projects, especially when using reclaimed, non-standard, or antique bricks, seeking help from professionals or local suppliers can prevent frustration and wasted resources. This hands-on testing brings confidence and ensures your end product is functional and beautiful.

Considering the Weather and Environment

Mortar, much like brick, lives at the mercy of the climate it’s placed in. Any region prone to harsh winters, dramatic summer heat, or high humidity will subject mortar joints to added stress over the years of service. In freezing climates, the mortar that allows too much water absorption can result in “freeze-thaw” cycling, which leads to cracked, flaked, or powdery joints when the liquid expands during cold snaps. Coastal zones or areas near salt-treated roads face the risk of salt ingress, which can break down mortar and brick. Proactive environmental consideration doesn’t stop at mortar selection. Mixing and application should be timed to avoid baking sun or freezing nights. On hot days, pre-wet the bricks and shield the new mortar from rapid drying. In colder seasons, curing should be extended and mortar kept above freezing. Minor adjustments and careful scheduling deliver big dividends in brickwork life span, saving on repairs and keeping masonry artistry looking top-notch for years.

Top Tips for Mixing and Application

Achieving a flawless brick bond comes down to precision at the mixing stage, attention to detail during application and patience. Always stick to the manufacturer’s recommended proportions, as varying too far can yield weak or excessively rigid joints. Use clean, sharp sand and potable water to prevent contaminants from affecting the setting or color. Gradually add water until the consistency resembles wet peanut butter—a mix that’s too runny will shrink and crack, while one that’s too dry is tough to work and may fail to bond.

When applying, avoid spreading mortar on a section that is too large at once. Only cover small areas you can brick before it dries or becomes unworkable. Insert bricks with a gentle twist to seat them firmly and expel air. Protect the setting mortar from direct sunlight, strong winds, or freeze risk for at least 48 hours post-application. These practical tips take just minutes but can distinguish between a wall that lasts a lifetime and one that fails early.

Common Mistakes to Avoid

Many brickwork failures can be traced back to a handful of classic mistakes. Selecting a too strong mortar for the brick, especially on restoration projects, can cause historic masonry to deteriorate rapidly, pushing softer bricks to break instead of flexing with the wall. Skipping the sample test might save an hour or two, but it’s a shortcut that often leads to color, texture, or set time mismatches, making repairs obvious and less attractive. Weather misjudgments are just as problematic. Applying mortar in unsuitable conditions—extreme cold, heat, rain—prevents proper curing, leading to weak or crumbly joints later. Lastly, letting mixed mortar sit too long before application will often reduce its workability, making it difficult to spread and less likely to bond. Planning and mindfulness can save countless hours in remediation and ensure a happier result.

Conclusion

Choosing the right mortar for your brickwork project is not just a technical step—it’s a cornerstone decision that affects your structure’s performance, appearance, and lifespan. From understanding the different mortar types to accounting for environmental conditions and ensuring proper application, every phase creates resilient, beautiful masonry. With careful planning, adherence to best practices, and consultation with professionals when needed, you can avoid common pitfalls and ensure a strong, lasting bond between your bricks. Whether you’re working on a new build, a restoration, or a decorative feature, the right mortar choice helps bring your vision to life while safeguarding it for years.